Skip to content

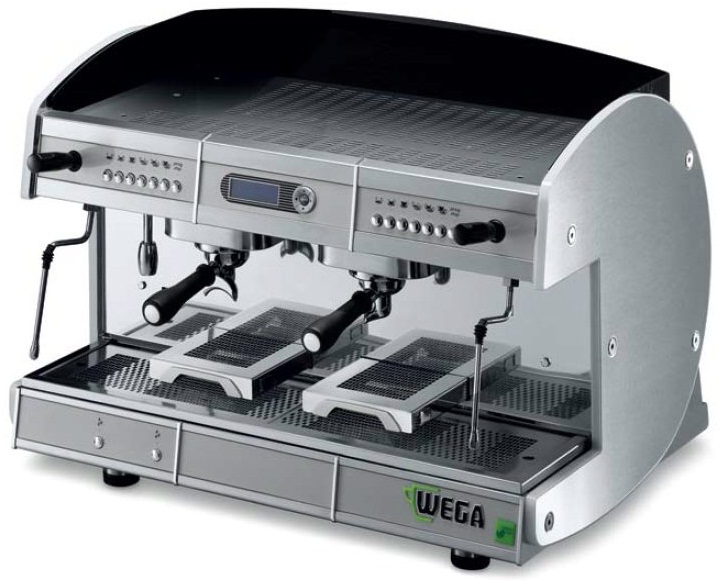

WEGA POLARIS

Price: Call For Quotation

Description

Green line espresso coffee machine

- Multiple boiler technology

- Self learning software

- Nocturnal standby mode

- 5 separate safety features on the services boiler, and 4 separate safety features on the individual coffee brewing boilers

Standard Equipment

- Boiler for each brewing group, in copper and brass, with a 1,2 litre capacity, and 1150W heating element

- USB port for the uploading and downloading of settings and parameters, in addition to software upgrades

- Hot water for tea, obtained by mixing fresh water from the incoming line, and steam from the services boiler

- Electronically controlled cup warmer

- Temperatures in the individual coffee brewing boilers, the group heads, and the services boiler, electronically controlled with a maximum fluctuation of 0,5°C either way

- Pump operating water pressure reading, together with incoming water pressure visible on the display

- Ambient humidity reading obtained by means of a hygrometer, and visible on the display

- Incoming water pressure reading, visible on the display

Safety Features on the Service boiler

- The pressure switch disengages the power supply to the heating element if the pressure in the boiler reaches 1,5 bars

- Should the pressure switch malfunction, the boiler safety valve opens when the pressure in the boiler reaches 2,0 bars

- A temperature sensor, disconnects the heating element when it reaches 130°C, and gives a visual alarm signal on the display

- A secondary safety sensor positioned internally in the boiler, disconnects the heating element should a temperature of 169°C be reached

- A function on the Central Processing Unit, disconnects the heating element should it work uninterruptedly at 100% of its capacity for longer than 60 seconds

- Time and date settings and visualisation

Safety Features on the Service Boiler

- The pressure switch disengages the power supply to the heating element if the pressure in the boiler reaches 1,5 bars

- Should the pressure switch malfunction, the boiler safety valve opens when the pressure in the boiler reaches 2,0 bars

- A temperature sensor, disconnects the heating element when it reaches 130°C, and gives a visual alarm signal on the display

- A secondary safety sensor positioned internally in the boiler, disconnects the heating element should a temperature of 169°C be reached

- A function on the Central Processing Unit, disconnects the heating element should it work uninterruptedly at 100% of its capacity for longer than 60 seconds

Safety Features on the Individual Coffee Brewing Boiler

- A temperature sensor, disconnects the heating element when it reaches 130°C, and gives a visual alarm signal on the display

- A secondary safety sensor, disconnects the heating element should a temperature of 150°C be reached

- The SNCR valve opens when the pressure in the hydraulic circuit surpasses 12,5 bars

- A function on the Central Processing Unit, disconnects the heating element should it work uninterruptedly at 100% of its capacity for longer than 45 seconds

Display Features

- Quantification and memorizing of selections effected by each group

- Option to control “save energy” function either manually or electronically

- Diagnostic messages obtained and displayed, in order to facilitate the operation of the Wegaconcept, in addition to the viewing of service and maintenance schedules

- Message indicating the necessary regeneration the water softener resins, or the substitution of the water filter cartridge

- Visualization of the machine parameters, including the primary and secondary menu options

- Time and date settings and visualization

Page load link